Add:Room506、507、88 Nanxijiang Road,Wuzhong District, Suzhou City ,China

Tel:+86-512-66267500

Fax:+86-512-66262500

Mobile:+86-15995883441

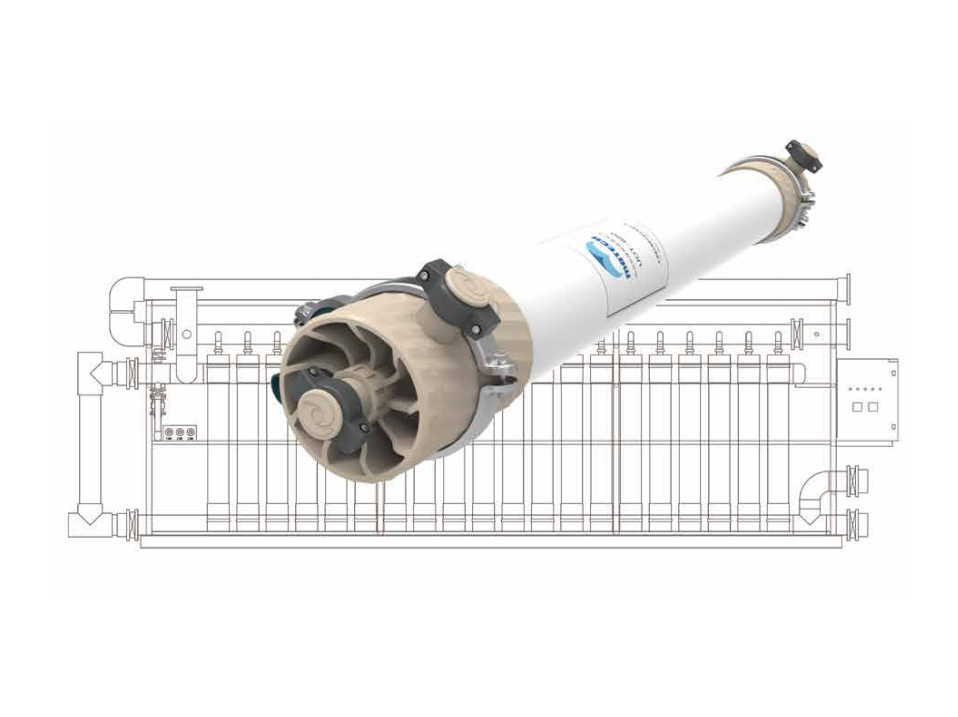

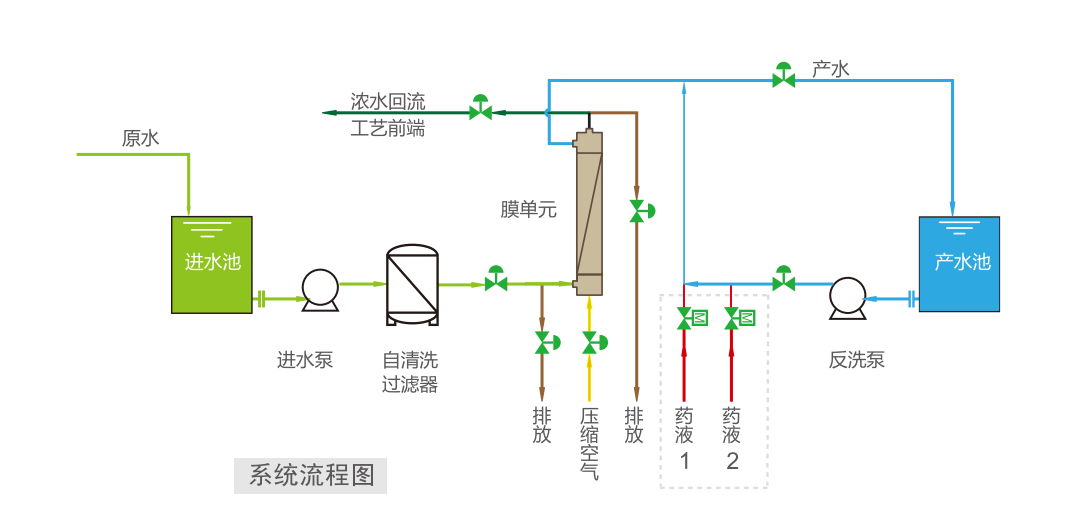

Continuous membrane filtration (CMF) technology is one of the internationally leading membrane filtration technologies dealing with water purification. The CMF is based on hollow fibre ultrafiltration / microfiltration membrane module as the central processing unit, with specially designed piping, valves, self-cleaning unit, plus chemical dosing devices, forming a continuous closed-loop system.Raw water is drawn through the microfiltration / ultrafiltration membrane filters at a defined pressure for purification to achieve physical separation. Its core technology is the high-performance membrane modules of anti-pollution , matches with the unique membrane cleaning technology.

Continuous membrane filtration (CMF) technology is one of the internationally leading membrane filtration technologies dealing with water purification. The CMF is based on hollow fibre ultrafiltration / microfiltration membrane module as the central processing unit, with specially designed piping, valves, self-cleaning unit, plus chemical dosing devices, forming a continuous closed-loop system.Raw water is drawn through the microfiltration / ultrafiltration membrane filters at a defined pressure for purification to achieve physical separation. Its core technology is the high-performance membrane modules of anti-pollution , matches with the unique membrane cleaning technology.

MOTIMO has the independent intellectual property rights on the integral technique ,21 patents ensure that our technologies and products have always been at the forefront of the world.

1.High anti-pollution of polyvinylidene fluoride (PVDF) membrane materials,antioxidation, fouling resistant, easy to wash;

2.high flux, producing a stable effluent, and has a long service life;

3.Simple device control, the system can run automatically,and can possibly be controlled remotely;

4.Unique online air–water backwashing methodology, excellent recovery rate of flux, lower self-expense water cost;

5.Covers an small area, compact modular design for the size of the difference in treatment;

6.Ultra-low-pressure operation, energy-saving;

7.Industrial chemicals can be used to clean the system, and save the running costs;

8.high water quality, high water recovery rate, effective water-saving;

Pretreatment system |

Since clean strainer |

airing system |

compressor,Air tank |

water supply system |

water conveying pump |

Dosing system |

Dosing pump,Dosing cans |

Host system |

Membrane modulemachines |

Cleaning system |

chemicals,Cleaning pump,Wash tank |

backwash system |

Reverse-wash pump |

Control systems |

PLC,Control cabinet |

Component models |

UOF-640 |

UOF-865 |

UOT-650 |

UOT-880 |

|

Component |

Membrane technology |

NIPS |

C-TIPS |

||

Effective membrane area (m2) |

40 |

65 |

50 |

80 |

|

Maximum diameter hole(um) |

0.03 |

||||

Component size |

1880×φ160 |

1985×φ225 |

2280×φ160 |

2360×φ225 |

|

component |

Moist component (kg) |

25 |

50 |

35 |

70 |

Overflw component (kg) |

40 |

85 |

50 |

105 |

|

Operating conditions |

Filter type |

Full fluxoid filter or cross flow filter |

|||

Maximum enter water pressure(KPa) |

200 |

350 |

|||

Maximum transmembrane differential pressure(KPa) |

150 |

300 |

|||

Applicable temperature range(℃) |

1-40 |

||||

Common PH range |

6-8 |

||||

Tolerance PH range |

1-10 |

||||

20℃design flux (L/m2*h) |

30-80 |

||||

Steam rage (Nm3/h) |

4-6 |

6-8 |

8-12 |

12-18 |

|

Steam rate (m3/h) |

0.3-0.5 |

0.5-0.8 |

1.0-1.4 |

1.8-2.2 |

|

Backflush water flow rate(m3/h) |

2.3-2.5 |

4.3-4.8 |

No water recoll |

||

|

|||||